MENU

Use Japanese Panasonic PLC and high-resolution light-touch multifunctional touch screen to make clear display of operating speed, temperature, operation and programming.

The microcomputer intelligently controls the stitching speed and temperature, and can be programmed at any time according to the needs of users

Adopting independent motor to control automatic tape feeding, automatic tape loosening, and automatic tape cutting structure design to reduce the loss of tape during operation and ensure product quality.

1.Display: 4.3inch color touch screen and can directly show all kids of data.

2. Temperature control: Temperature is automatic tracking controlled by computer and its precision can reach ±1℃.

3. Speed Control: The temperature is controlled by computer chip, two stepper motor, separate upper and lower roller motor, can be

adjusted its speed, synchronous and differential work, ideal for elastic fabric and the pleated sewing.

4. Protective Measures: Turn on the heating button, later turn it off and then delay the shut down, get into count down in order to protect the heating tube.

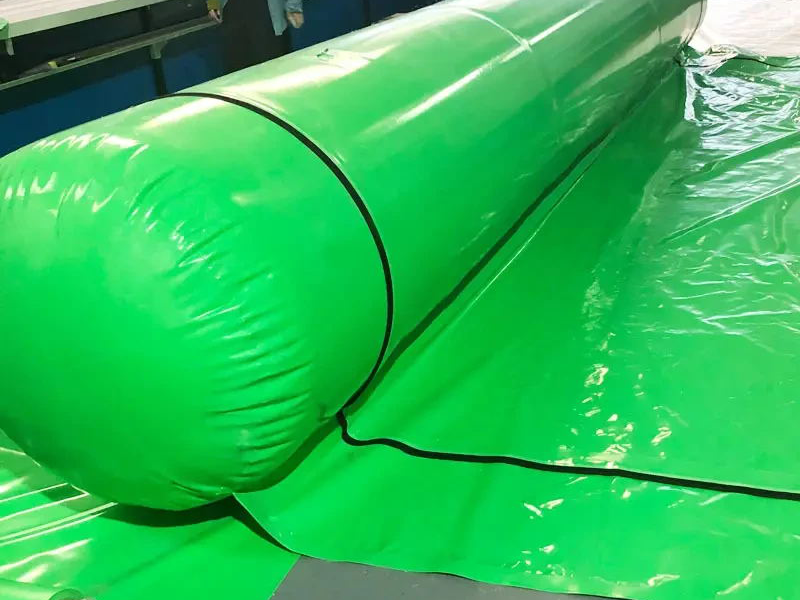

5. Whole design: No table, extra-wide lower prop design, adjustable angle of the lower prop, suit to processing the large tents, rubber boats, air balloon, seamless sewing products etc.

| Model | WELD-15 |

| Power | 3KW |

| Power Supply | 220V 50Hz |

| Temperature of Heating Control | Up to 700℃ for hot air Heat control |

| Temperature of Hot Wedge | Up to 450℃ for hot wedge |

| Speed | 1-18m/min |

| Pressure | 0.35-0.5Mpa |

| Pinch Roller Width | 20/30/40/50mm |

| Nozzle Width | 20/30/45m |

| Option Function | Hot Wedge |

| Dimansion | 1500MM*750MM*1600MM ( L*W*H) |

| Net Weight | 245KG |