MENU

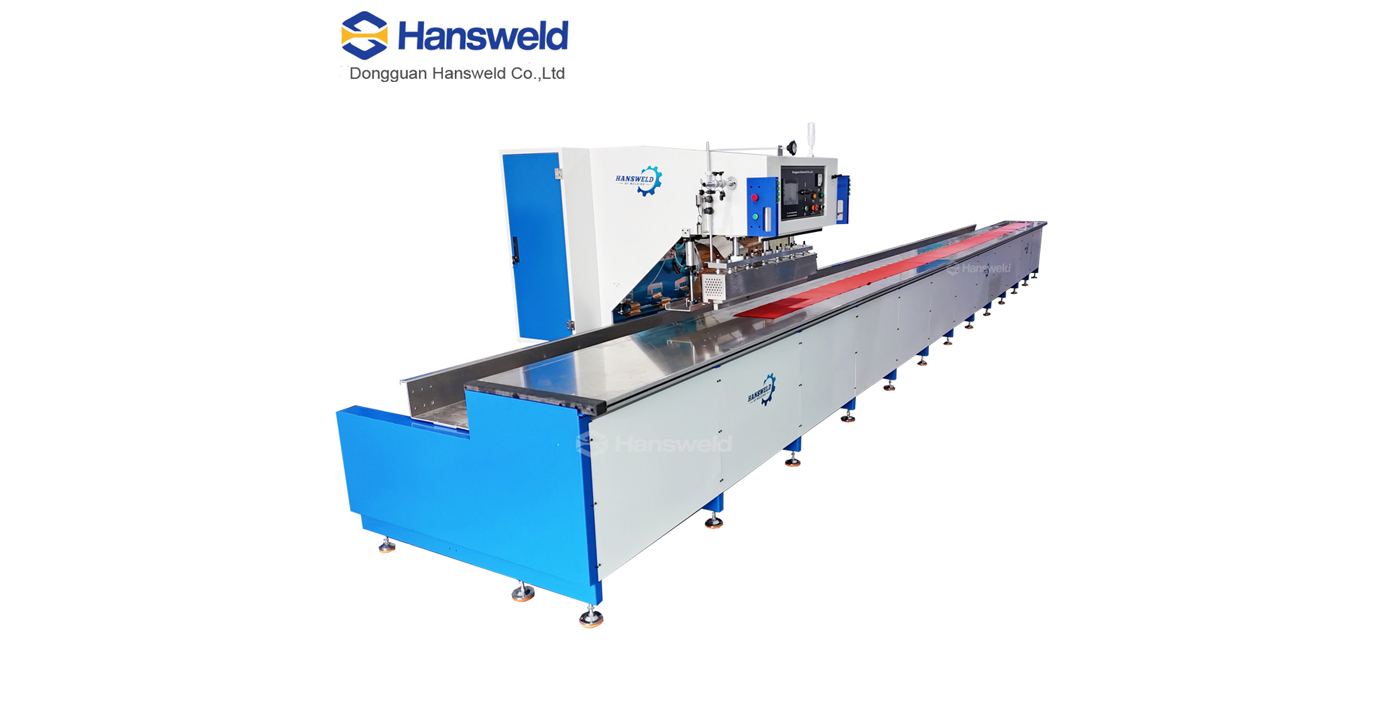

High frequency membrane structure welding machine is a kind of equipment specially used for welding and splicing various soft materials, mainly suitable for materials containing more than 10% PVC such as PVC/TPU/PU/EVA/PTFE/PVDF/ETFE.

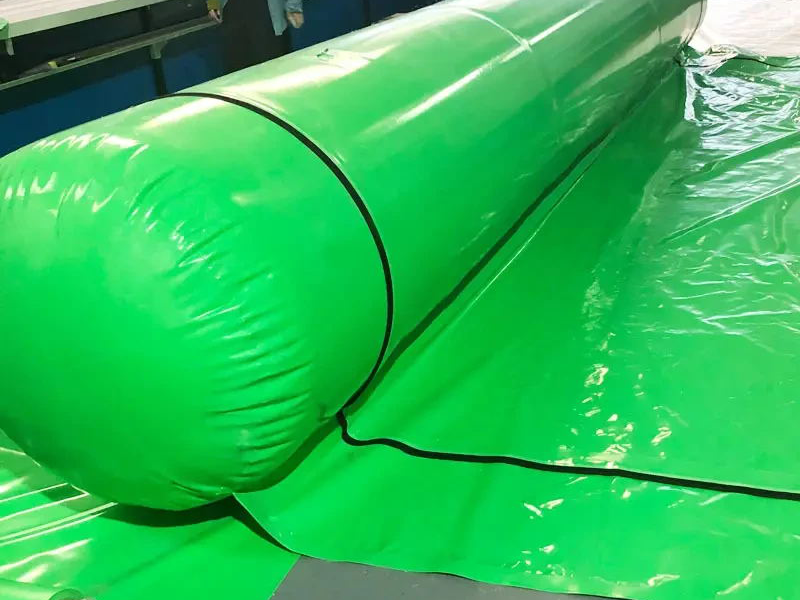

It is widely used in tents, parking sheds, tensioned membranes, space membranes, architectural membrane structures, water bags, pools, water beds, inflatable water toys, hot air balloons, soft biogas tanks, bridges, water bags, PVC rolling doors, liquid chemical transport bags, car tarpaulin canvas connection, movie curtain welding, outdoor membrane welding, outdoor awning welding, advertising inkjet cloth welding and other fields.

1.Efficient welding: The welding speed is fast, up to 3-6 meters per minute, suitable for continuous large-scale welding operations.

2.High flexibility: Machines with different power sizes can be selected according to user needs, and the size of the high-frequency mold can be changed to adapt to the welding of materials of different lengths and widths.

3.Automatic welding: There is a stacking trough with corresponding span on the inside of the machine. The span and depth of the stacking trough can be selected according to the size of the welding product to achieve automatic welding and docking.

4.Protective device: Equipped with anti-spark protection device and controllable current electrorheology to prevent damage to the mold and high current protection function to ensure equipment safety.

5.Anti-electromagnetic wave shielding: The equipment is equipped with an anti-electromagnetic wave shielding device to reduce the impact of electromagnetic waves on the human body.

6.Stable and reliable: The special body structure and thickened steel plate are used to ensure stability and reliability when processing different products.

7.Intelligent operation: Some models are equipped with an intelligent PLC human-machine interface operating system to achieve automatic walking and precise positioning, improving work efficiency.

| Model | WELD-M-15KW | WELD-M-25KW |

| Suitable Welding Area | 30MM*1000MM | 50MM*1000MM |

| Voltage | AC3∮ 380V 50HZ | AC3∮ 380V 50HZ |

| Control Method | PLC/man-machine interface | PLC/man-machine interface |

| PLC | Delta | Delta |

| Servo | Delta | Delta |

| Oscillating Frequency | 27.12Mhz | 27.12Mhz |

| Maximum working pressure | 1000KG | 1500KG |

| Oscillator | 8T85RB | 8T25RA |

| Groove Size | 500*200MM | 500*200MM |

| Alignment System | Imported Rail | Imported Rail |

| Rectifier | Silicon Diode | Silicon Diode |

| Pressurization Method | Airtec | Airtec |

| Machine Color | White / or Customized | White / or Customized |

| Effective Track Length | According to customer requirements | According to customer requirements |

| Contactor and Switch | CHNT | CHNT |

| Time Relay | OMRON | OMRON |

| Pneumatic Components | Airtec | Airtec |