MENU

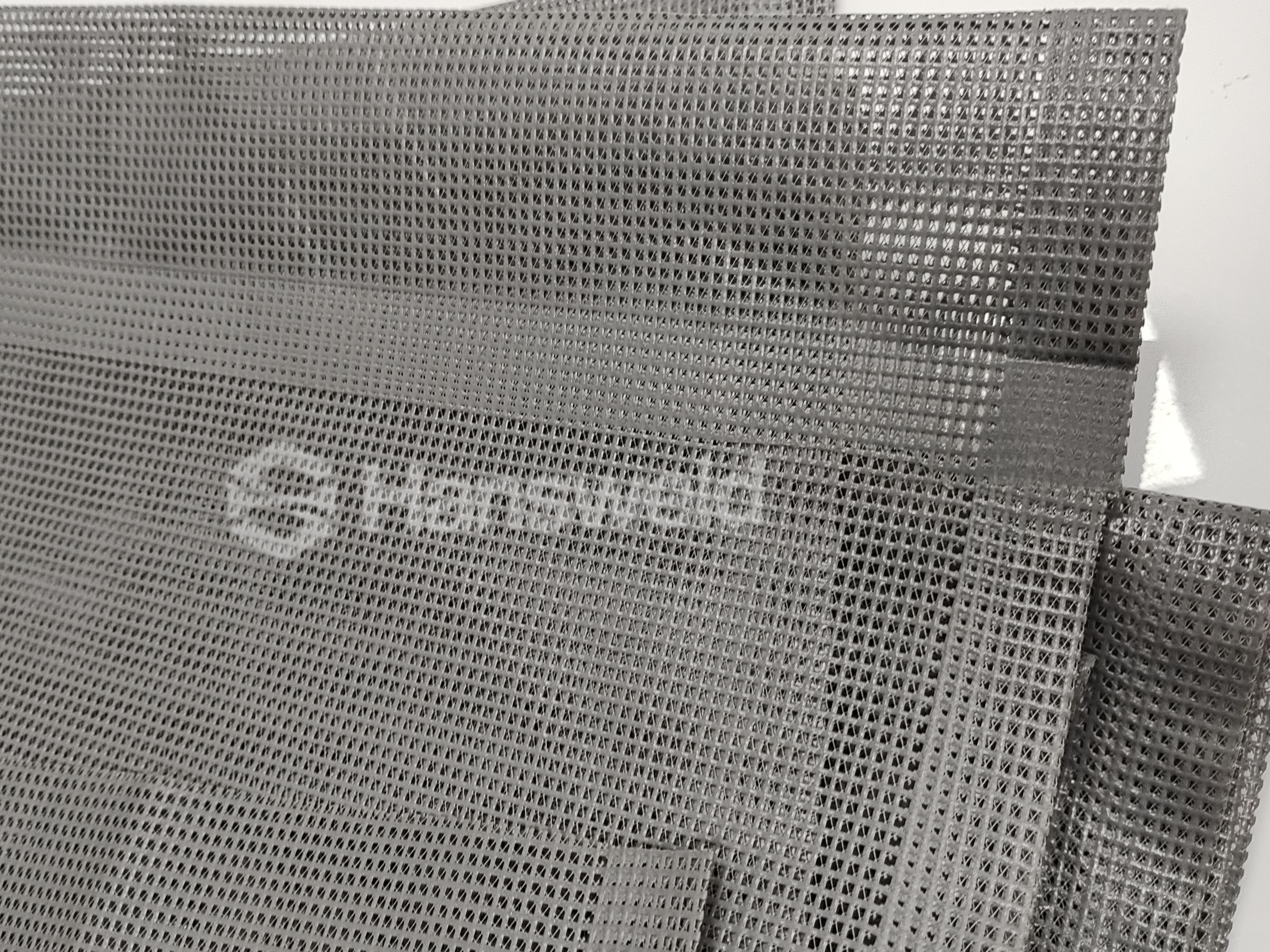

High frequency membrane structure welding machine is a kind of equipment specially used for welding and splicing various soft materials, mainly suitable for materials containing more than 10% PVC such as PVC/TPU/PU/EVA/PTFE/PVDF/ETFE.

It is widely used in tents, parking sheds, tensioned membranes, space membranes, architectural membrane structures, water bags, pools, water beds, inflatable water toys, hot air balloons, soft biogas tanks, bridges, water bags, PVC rolling doors, liquid chemical transport bags, car tarpaulin canvas connection, movie curtain welding, outdoor membrane welding, outdoor awning welding, advertising inkjet cloth welding and other fields.

1.It can choose machines with different high-freauency powers accordind to the needs of users, The lenath. curvoture and width of weldindmaterials can be changed each time. and the size, enoth and width of hiah-freauency molds con be chanaed to meet the needs of flmstructure welding.

2.The high-frequency oscillation system is a European-style square coaxial structure, and the high-frequency output power is stable andpowerful.

3.The high-frequency 5557 spark protection system is installed in the high-frequency welding machine to prevent damage to the high-requency welding mold.

4.The welding time can be set freely according to the thickness of the material, and the high-frequency power output can be preciselyadjusted.

5.lt welds firmly, and the thickness of the material can be satisfied. The deep and wide feeding tank of the machine is convenient for large-area continuous connection. The machine can be rotated for continuous crimping and welding, and the round-trip length can be customizedreely.

| Model | WELD-750 |

| Power Range : | 10KW |

| Input Power: | 18KVA |

| Suitable Welding Area | 250CM2 |

| Oscillation Tube | E3069 |

| Standard working table | 450*1050MM |

| Power Supply | 3P * 380V * 50Hz & 3P * 220V * 60Hz |

| Working Frequency | 27.12Mhz |

| Rectifier | Silicon Diode |

| Drive Mode | Pneumatic ( Hydraulic optional at additional cost ) |

| Arc suppressor | High Sensibility NL-5557 |

| Suitable Material : | PVC or any fabric contents PVC . |

| Cylinder working stroke | 150mm ( customization offered ) |

| Welding Time | 0-30 S adjustable ( customization offered ) |