MENU

Packaging industry:

such as blister, PVC plastic blister, PETG blister, toothbrush sealing packaging, blister paper card packaging, etc.

Suitable for heat-sealing production and processing of various packaging bags, hand warmers, portable soft bags, etc., including left and right blister heat-sealing trimming, blister and cardboard heat-sealing trimming, etc.

Garment processing industry:

High-frequency fusing machine is used for welding and processing of materials such as PVC, TPU, EVA, PETG, etc., and is suitable for the production and processing of PVC thermoplastic resins such as leather products and pure cotton cloth.

It can be used for embossing processing of various garments, such as leather product embossing, artificial leather embossing, polar fleece embossing, PVC leather embossing, etc.

Automobile industry:

High-frequency fusing machine is widely used in the automotive interior parts industry, such as automobile seat ventilation bag welding machine, automobile filter element welding machine, automobile massage chair air cushion heat sealing machine, etc., for sealing packaging of double-sided blister of PET, PETG, GAG environmentally friendly materials, welding of automobile seat back cushions, etc.

Medical supplies industry:

The medical blood bag high-frequency welding machine uses the principle of high-frequency electromagnetic field to ensure the sealing and safety of blood bags.

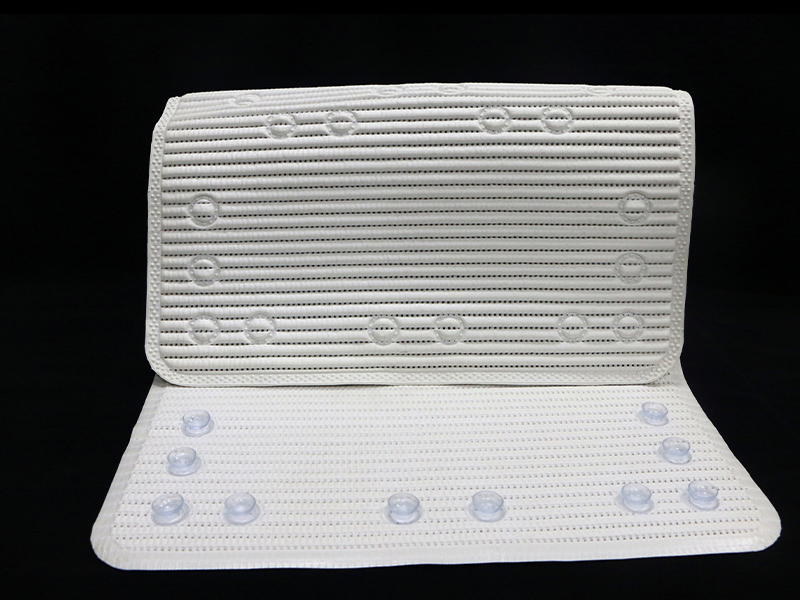

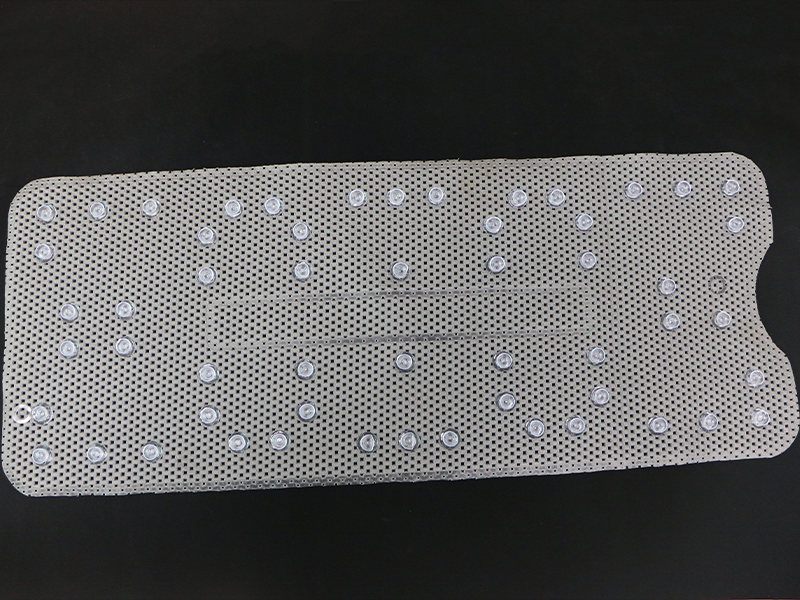

The medical ice pad high-frequency fusing machine is used to make medical ice pads. The material is quickly melted at a specific position through the instantaneous high temperature of the high-frequency electromagnetic field.

Other industries:

The high-frequency fusing machine is also used in the processing of heat welding and sealing of various plastic products, such as battery packaging sealing, hardware tool sealing, U disk packaging sealing, computer memory card blister packaging factory sealing. It is suitable for the welding and fusing of various trademarks, watch straps, belts and other products.

1. Strong output and excellent performance;

Using a low-loss coaxial oscillator and a specially designed synchronizer, the output is enhanced, the splicing time is reduced, and the production efficiency is improved.

2. High sensitivity spark arrester;

This machine adopts a newly designed electronic circuit spark arrester with high technical level, which is highly sensitive, stable and reliable, and can minimize the damage caused by sparks to molds, materials, insulation materials, etc.

3. Safety protection device;

This machine is equipped with over-voltage and over-current protection devices, which can automatically cut off the power supply or shut down when abnormal conditions occur, protecting valuable components such as the oscillation tube from damage.

4. High reliability and high efficiency;

This machine adopts a pneumatic pressurizing mechanism to ensure consistent product fusion and improve product quality. Use high-quality and reliable parts to minimize the maintenance rate of the equipment.