MENU

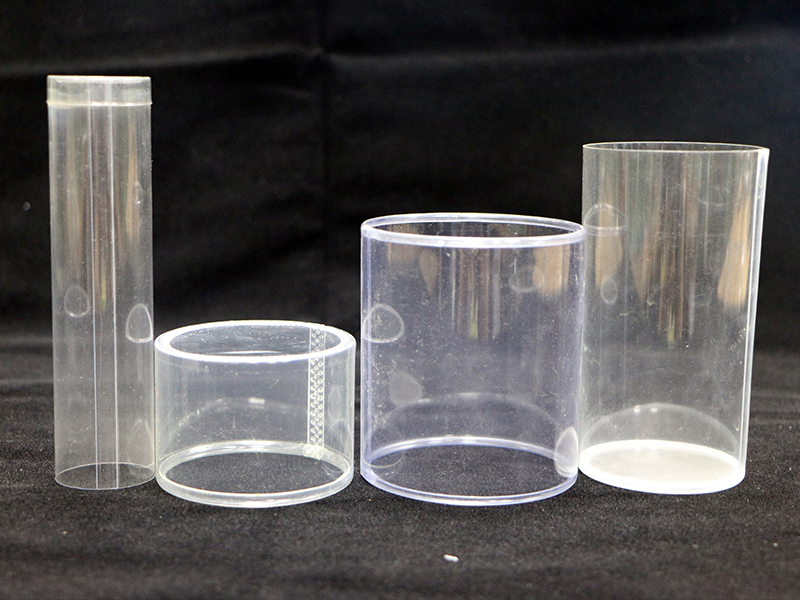

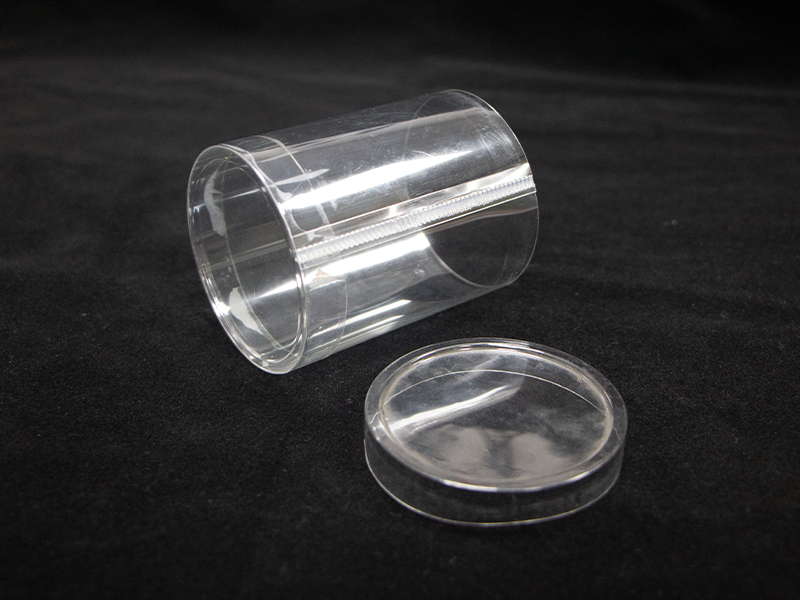

The automatic cylinder forming machine is designed for PVC, PET, APET, PETG, PP and other plastic cylinders.

The operation of this machine is simple: the material does not need to be leveled and cut, the coil is automatically completed on the machine, the system will automatically cut it according to the required length, the speed is fast, accurate, saves man-hours, and replaces the traditional single production method, the size of the finished product is consistent, the appearance is perfect without scratches, and the equipment can be equipped with an ultrasonic welding system, which has a wide range of applications.

The cylinder products manufactured by this machine are widely used in chocolate, candy, biscuits, cosmetics, toys, handicrafts, electronics, hooks, sanitary ware, brushes, tea, food, medicine, machinery, culture and sports, daily necessities and other industries.

1. Ultrasonic function, automatic glue brushing function

2. PET brushing UV lamp function, optional configuration

3. Automatic punching function, optional configuration

4. The height of the product is max.400mm, and the diameter is max.200mm

5. SMC takes the finished pneumatic components, the speed is fast and there is no error

6. PLC touch screen control, easy to operate

7. The bonding effect is beautiful and firm, and there is no scratching wolf

| Model | HSD-200 |

| Power supply | 220V 50Hz |

| Cylinder diameter | 38-200mm |

| Cyinder length | 20mm-2000mm |

| Material thickness | 0.18mm-0.45mm |

| Productivity ( ultrasonic ) | 50Pcs/Min(Length 100mm) |

| Productivity ( gluing ) | 60Pcs/Min (Length 100mm) |

| Control system | PLC Controlling |

| Dimension | 4250mm×780mm×1690mm (L*W*H) |