MENU

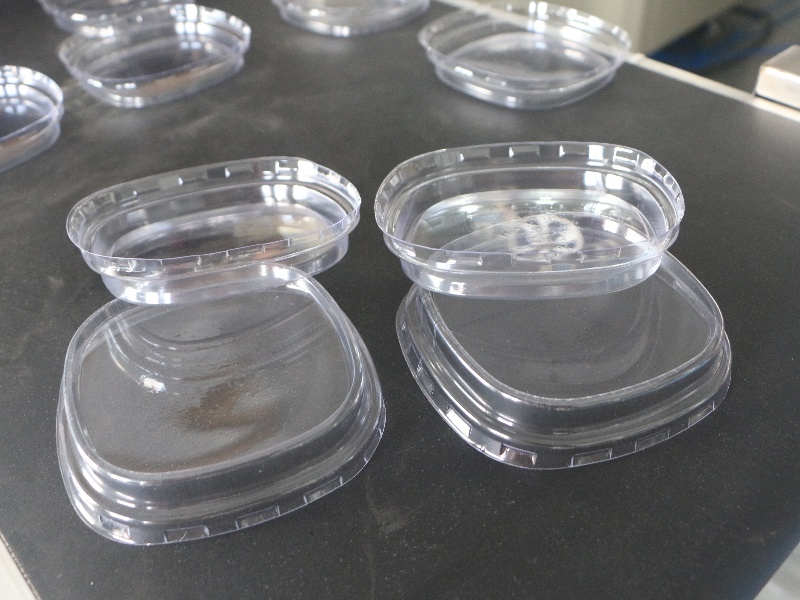

Fully automatic cylinder bottom cover forming machine is used for: forming of PVC cylinder bottom cover, APET cylinder bottom cover, PETG plastic cylinder bottom cover.

Gifts, medicine, food, building materials, metallurgy, chemical industry, environmental protection and many other production industries

1.Food industry: food packaging, beverage packaging, candy packaging, etc., used to make food-grade cylinder covers.

2.Daily necessities industry: toiletries packaging, cosmetics packaging, personal care products packaging, etc., suitable for the production of cylinder covers for various daily necessities.

3.Hardware industry: hardware tool packaging, small metal product packaging, etc., used for the forming of metal cylinder covers.

4.Pharmaceutical industry: drug packaging, medical device packaging, etc., to ensure the hygiene and safety of products.

5.Chemical industry: chemical product packaging, plastic barrel packaging, etc., suitable for the packaging of various chemical raw materials.

6.Environmental protection industry: environmentally friendly product packaging, degradable material packaging, etc., in line with environmental protection requirements.

7.Gift industry: gift packaging, souvenir packaging, etc., used for the production of cylinder covers for various gifts.

8.Toy industry: Toy packaging, stationery packaging, etc., suitable for the production of cylinder covers for various toys and stationery.

9.Building materials industry: Building materials product packaging, pipeline packaging, etc., used for the molding of cylinder covers for various building materials

1: Realize GMP/QS dual standard dust-free purification production, improve product hygiene and safety, and solve cross contamination;

2: Unwinding, forming, punching, blanking, discharging, counting, and winding are seven stations for synchronous automatic production. The manipulator (pneumatic) clamps and feeds, the mechanism is compact, the operation is stable, and the operation is simple;

3: The stations are modularized, the tooling is unified, and the accuracy is ensured. Each station is adjusted as needed by the hand wheel, and the stroke can be adjusted arbitrarily, making it easy to change molds and adjust the stroke;

4: This equipment uses human-machine interface and PLC control, encoder support, variable frequency speed regulation, beautiful and easy to operate;

5: The intelligent type can be equipped with servo traction, and the traction length can be set arbitrarily on the touch screen within the traction size range. The traction length can reach 280mm;

6: Customized equipment and molds can be designed according to user requirements.

| Model | HSD-4020T |

| Power | 4.5KW |

| Power Supply | 3P*380V |

| Fuction | Forming/Cutting |

| Film Thickness | 0.15mm-0.5mm |

| Hydraulic Pressure | 0.2mpa |

| Gas Consumption | 0.3m 3/h(Cooling Water) |

| Air Supply | 0.5-0.7mpa |

| The Number of Times | 20-30 Times/Min |

| Machine Size | 1520mm*760mm*1560mm(L*W*H) |

| Maximum Forming Area | 420mm*200mm |

| Maximum Forming Depth | 50mm |