MENU

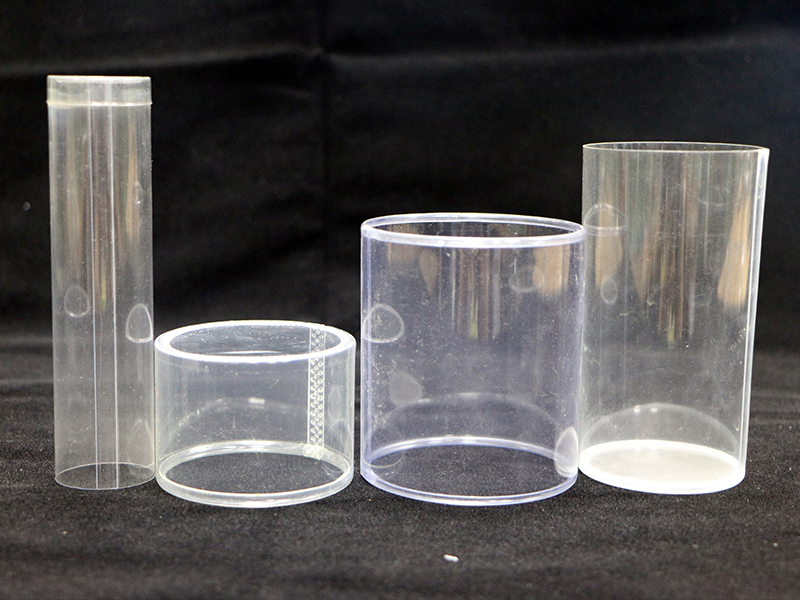

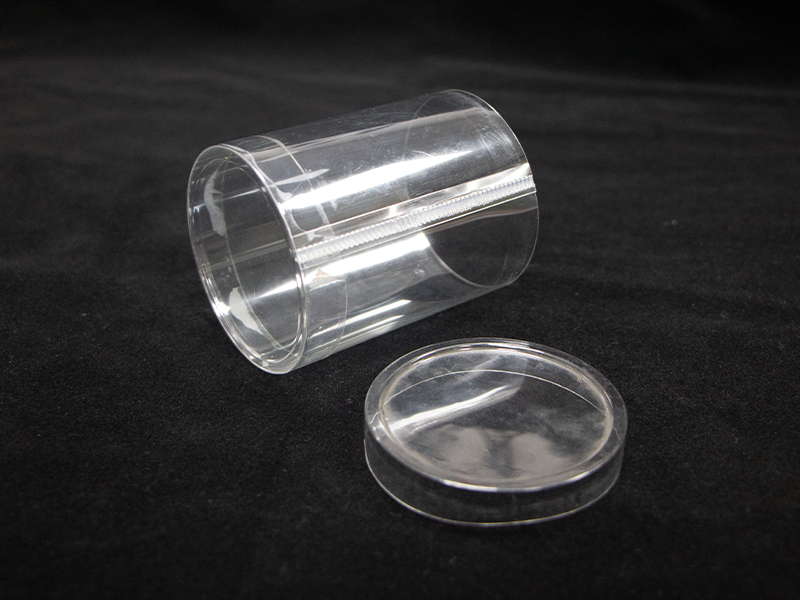

It is suitable for mass packaging production of PVC cylinder packaging, APET cylinder packaging, PETG cylinder packaging, plastic conical cylinder packaging, plastic cylinder packaging, paper cylinder packaging and other plastic transparent conical cylinders.

It is an ideal packaging container for candy packaging, gift packaging, toy packaging, stationery packaging, umbrella packaging, fishing gear packaging, badminton packaging, tablet packaging, tablet-type leisure food packaging and other products.

1. Use advanced glue spraying technology to ensure that the bonding position of the cylinder is transparent, beautiful, not whitish, and has no bubbles. The bonding of PET cylinders is transparent and not whitish, and the bonding of PVC cylinders is transparent and full of glue, and the amount of glue spraying can be adjusted.

2. The quality of the new machine is guaranteed and the performance is more stable. The PLC control system, circuit electronic components and cylinders are all from Taiwan and foreign brands, ensuring the stable performance and durability of the machine.

3. The CNC system of the semi-automatic cylinder machine can be set to start automatically according to time, and the production efficiency is increased by 30%. Only manual feeding is required, and the machine takes down the cylinder. The action of pressing the start switch (foot switch) by hand is omitted. Thereby reducing the cylinder production time and improving production efficiency. If this automatic start function is not needed, you can click to close it in the PLC CNC system, and press the start button or foot switch by hand to produce.

4. Add a special glue tank. The gluing air pressure is more uniform, the glue spraying is more stable, and more importantly, the glue does not block the needle, thereby reducing the waste of time and needle replacement time, truly improving efficiency and reducing waste.

5. The machine mold is finely processed, and the cylinder molding precision is high. The two ends of the cylinder are flat and the size is consistent. The color printing of the cylinder body is neat and beautiful.

| Model | HSD-380 |

| Power supply | 1P *220V |

| Ratde Power | 1.5KW |

| Pneumatic Range | 3-6KG/CM2 |

| Diameter of Cylinder | 45-200MM |

| Thickness of Material | 0.18MM-0.55MM |

| Height of Cylinder | 0.18MM-0.38MM |

| Max Length of the tube | 3200M |

| Suitable Material | PVC or PET |

| Machine Size | 700MM*650MM*1000MM(L*W*H) |