MENU

The main uses of high-frequency machines are:

PVC, PU, TPU, EVA, PE, PET, and any other soft and hard rubber materials, as well as special purpose processing or vacuum packaging sealing of leather or woolen fabrics, are widely used.

Scope of use:

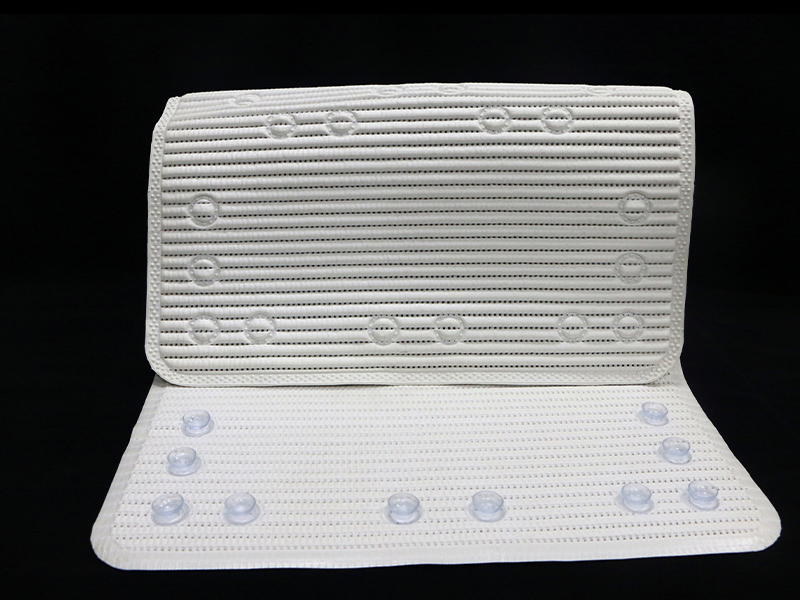

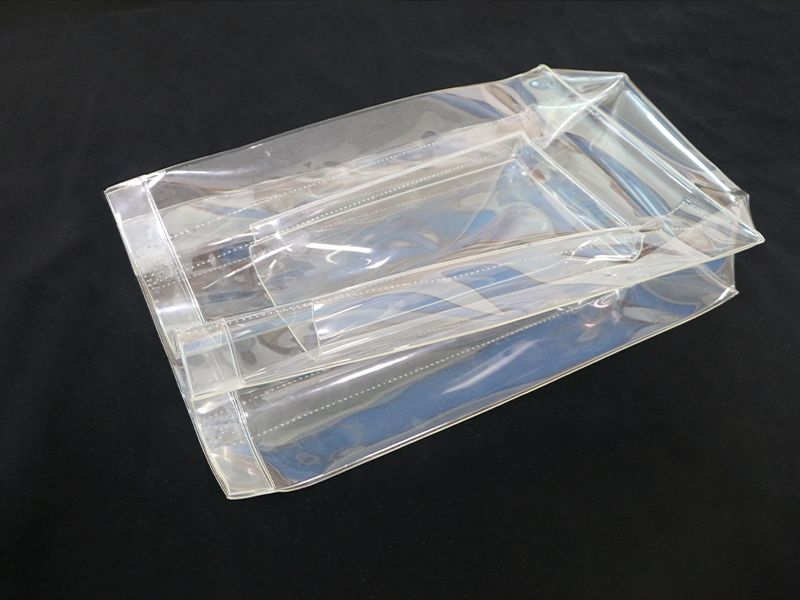

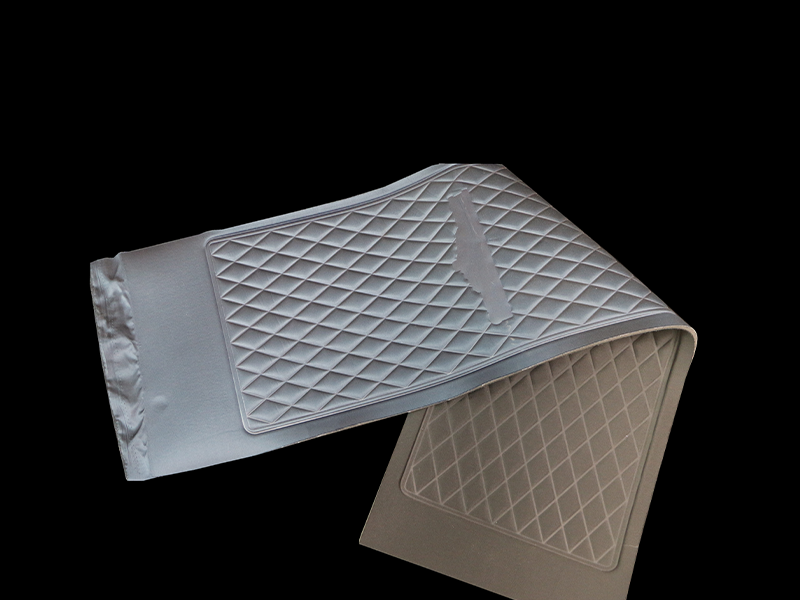

Such as embossed shoes, hats, clothing, craft accessories, inflatable toys, air cushion beds, car sunshades, foot cushions, cushions, car oil pots, and various automotive products, trademarks, bags, shower curtains, carpets, packaging bags, hot water bags, medical equipment, stationery, photo albums, albums, sports products, PVC folding boxes, eyeglass boxes, tents, motorcycle cushions, vacuum packaging and sealing of tools, electronics, and electrical appliances.

(1) Strong output, high performance, using a low-loss coaxial oscillator, which can make the output stronger, reduce the welding time, and increase the production volume.

(2) Electronic time controller can accurately control the welding time, adjust the setting time range from zero to ten seconds, and is easy to use.

(3) Equipped with a high-end 5557 spark protection device. When sparks are generated, the electronic circuit can automatically cut off the high-frequency output, effectively preventing mold damage.

(4) When the current exceeds the limit value, the load current relay automatically protects the oscillation tube and rectifier.

(5) High efficiency, high stability and simple operation.

(6) Install high-frequency frequency shielding and anti-interference devices to prevent interference with other electronic products and damage to your own electronic products.

(7) High-precision temperature control to ensure welding consistency.