MENU

High frequency leather embossing machine is mainly used for PVC, PET, PETG, EVA, AGA, APET, PU, TPU or any soft and hard plastic material with PVC content above 20%, as well as leather, genuine leather, fabric, composite plastic, mirror leather, artificial leather, composite leather, composite fabric and other special purpose product materials that can be produced and processed.

The processing methods include welding, heat sealing, sealing, embossing, fusion welding, and fusing.

Specifically, as follows:

1. Shoes and hats, ancient clothing, leather: embossed upper, welded sole, embossed insole, welded insole, embossed hat, embossed soft film ceiling.

2. Jewelry, Toy and Stationery: Crafts Welding, Jewelry Welding, Gift Packaging, Toy Welding, Toy Packaging, Toy Welding, Toy Embossing.

3. Leather and leather goods luggage category: leather welding, leather embossing, leather welding, leather welding, luggage embossing, towel embossing, leather embossing.

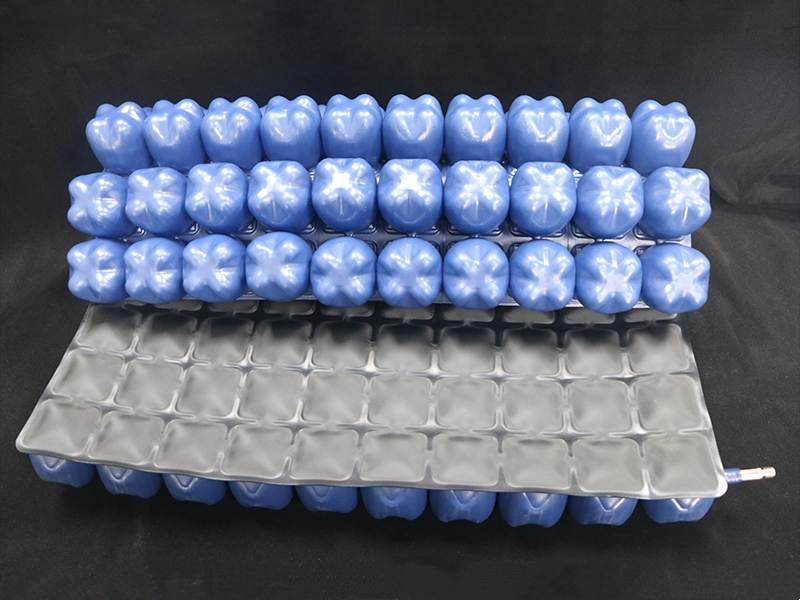

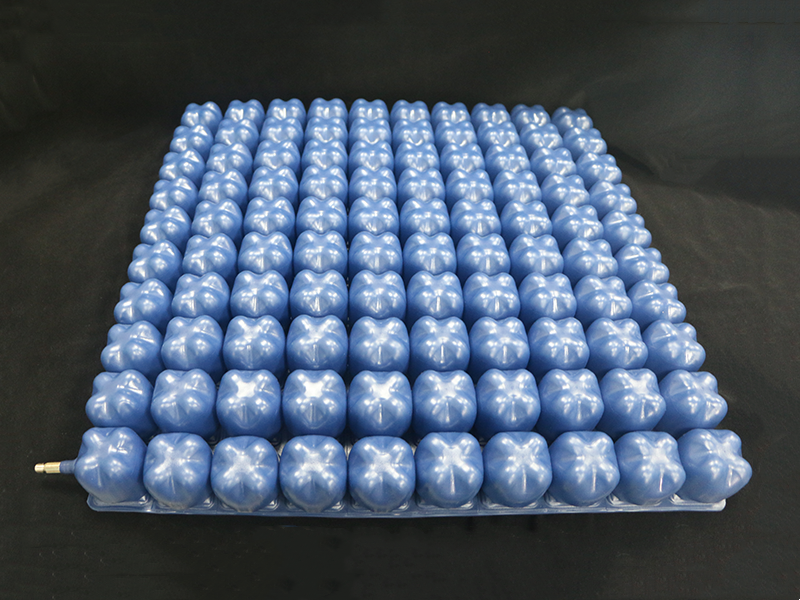

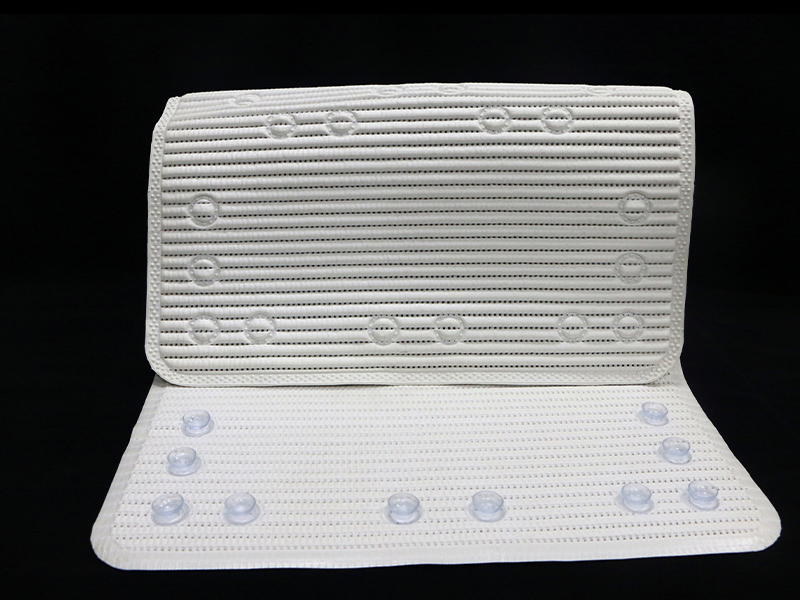

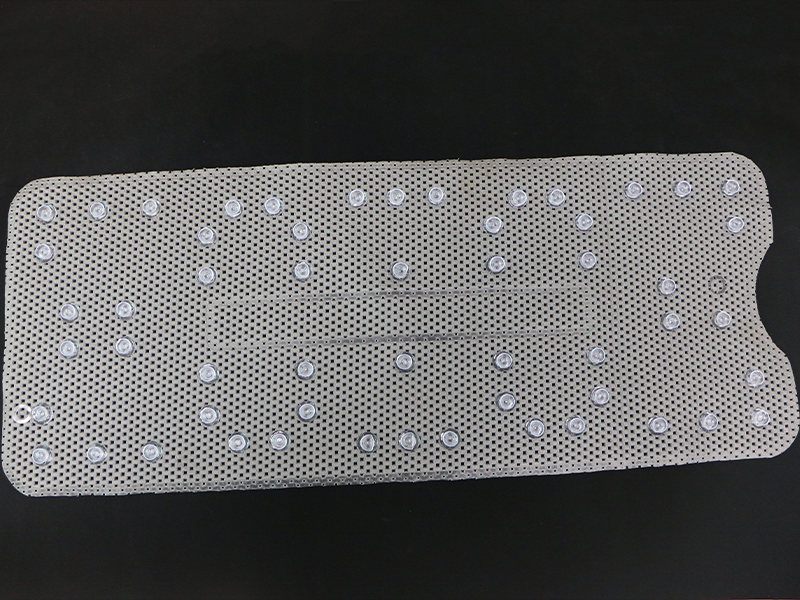

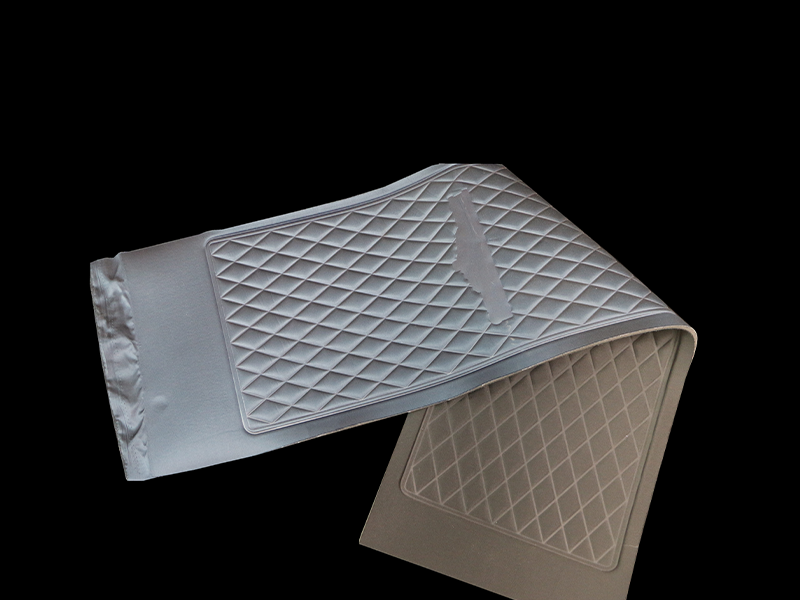

4. Door mat, foot mat, carpet category: PVC door mat embossing, door mat welding, plastic door mat embossing, carpet embossing, floor mat welding, foot mat embossing

5. Plastic packaging sealing category: plastic welding, packaging bag welding sealing, plastic welding, PVC packaging bags, hot water bags, electrical vacuum packaging.

6. Medical supplies and equipment category: disposable gift packaging, catheterization bags, catheterization bags, extracorporeal drainage bags, emergency stretchers, PVC oxygen masks.

7. Automotive interior products: gift packaging, car door panels, steering wheel covers, anti lattice welding, reflective sticker welding, reflective film welding.

(1) Stable weekly rate:Adopting the international industrial band of 27.12MHz, the output cycle is stable and meets the international industrial band standards.

(2) Strong output power: Low loss coaxial oscillator, synchronous tuner, strong output power, shortens fusion time, and improves output.

(3) Safety performance: Whether encountering a sudden power outage or gas outage, the machine remains stationary and will not suddenly rise or fall; Improve worker operation safety issues.

(4) High speed synchronizer: Adjusting according to the size of the product and the thickness of the material can greatly reduce the necessary welding time and increase the production capacity of the machine.

(5) Anti interference device: Equipped with a frequency stabilizer and a high-frequency magnetic field shielding system to reduce high-frequency interference.

(6) Reinforced rack: Stable and durable.

(7) Heating function: Suitable for different product processing needs.

(8) Left and right disc pushing operation: Suitable for thermal welding or sealing of large-sized plastic products.

| MODEL: | HSD-35KW |

| POWER: | 35KW |

| POWER SUPPLY: | 440V *3 P *60Hz |

| ELETRONIC POWER: | 60 HZ |

| RECTIFIER: | SILICON DIODE |

| Electronic TUBE: | FU-924 |

| PRESSURE: | 15T ( hydraulic ) |

| MAX GAP OF ELECTRODES: | 150MM |

| SIZE OF ACTIVE HORN: | 150MM |

| SIZE OF UP ELECTRODE: | 600*900MM |

| SIZE OF BOTTOM ELECTRODE: | 610*910MM |

| WELD TIME: | 0-30S adjustable |