MENU

Shoes, hats and clothing labels:

Shoe upper embossing, sole heat sealing, insole embossing and welding, hat embossing, clothing embossing, raincoat, raincoat heat sealing and welding, clothing labels, tag heat sealing, trademarks, badges, leather label heat sealing, flocking fabric embossing, etc.

Accessories, toys and stationery:

Crafts welding and heat sealing, accessories, gift packaging heat sealing, toys, stationery heat sealing and packaging, toy welding and embossing, business card inner pages,

Leather and leather goods and bags:

Leather embossing, embossing, labeling, luggage embossing, leather embossing, etc.

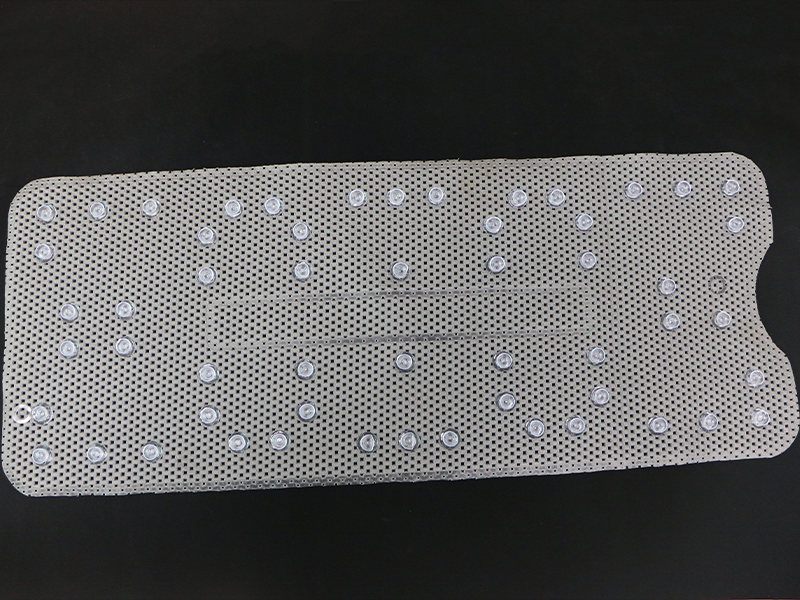

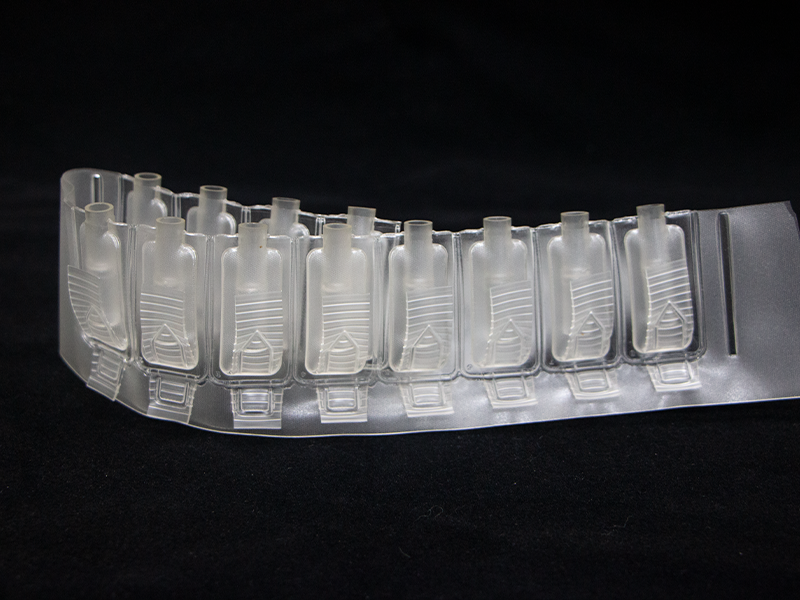

Plastic packaging sealing:

PVC, PS, PET, APET, PETG and other plastic materials heat sealing and welding, packaging bags, hot water bottles, electrical appliances blister packaging sealing, hardware tools, battery packaging sealing, electronic products blister sealing, toothbrush packaging, PVC folding box sealing, plastic embossing, etc.

(1) Strong output, high performance, using a low-loss coaxial oscillator, which can make the output stronger, reduce the welding time, and increase the production volume.

(2) Electronic time controller can accurately control the welding time, adjust the setting time range from zero to ten seconds, and is easy to use.

(3) Equipped with a high-end 5557 spark protection device. When sparks are generated, the electronic circuit can automatically cut off the high-frequency output, effectively preventing mold damage.

(4) When the current exceeds the limit value, the load current relay automatically protects the oscillation tube and rectifier.

(5) High efficiency, high stability and simple operation.

(6) Install high-frequency frequency shielding and anti-interference devices to prevent interference with other electronic products and damage to your own electronic products.

(7) High-precision temperature control to ensure welding consistency.

| Model | HSD-8KW |

| Power | 8KW |

| Input power | 8KVA |

| Power Supply | 380V 3P 50HZ |

| Frequency | 27.12MHz |

| Rectifier | Silicon Diode |

| Oscillation tube | 7T69RB |

| Max pressure | 500KG |

| Gap of electrodes | 250MM |

| Cylinder Stroke | 150MM |

| Size of upper electrode | 400*600MM |

| Size of bottom electrode | 400*600MM |

| Max Welding surface each work cycle | 200c㎡ |

| Welding time | 0-30s |