MENU

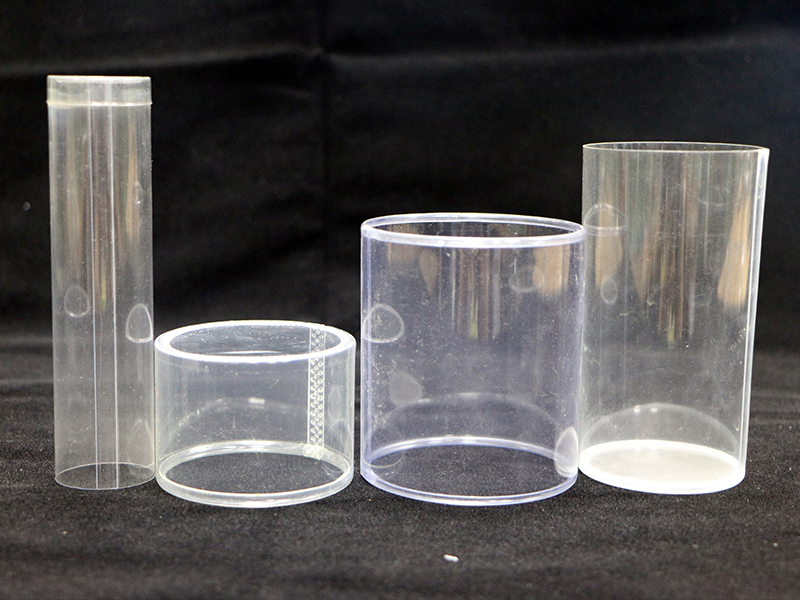

Daily chemical industry: Applicable to the packaging and sealing of hair care products, cosmetics, cleaning and washing products, etc.

Gift and craft industry: Applicable to the cylindrical packaging of various gifts and crafts.

Toy industry: Applicable to the cylindrical packaging and sealing of toys.

Hardware and machinery industry: Applicable to the cylindrical packaging and sealing of hardware and mechanical products

Automatic gluing and gluing: The machine can automatically gluing and gluing the cylinder cover and bottom film, which improves work efficiency and consistency.

8-station design: There are 8 stations, which can process multiple cylinders at the same time, suitable for mass production.

Adjustable speed: The speed of each station can be adjusted according to production needs to meet the sealing requirements of different products.

Replace manual work: Only one worker is required to operate, which greatly reduces labor costs and improves production efficiency.

High yield rate: The machine properly controls the time between sealing and workers taking out the product, the glue is basically solidified, and the bottom is firmly adhered, thereby improving the yield rate.

| Model | HSD-8G |

| Power supply | 3*P220V 2KW |

| Station | 8- workstations |

| Bottom cover diameter | 4-200MM |

| Thickness | 0.15-0.6MM |

| Demand air pressure | 0.6Mpa 350L/min |

| Production speed | 800-1000 pieces/hour |

| Adhesion accuracy | ≤±0.03PLC control, 8-position precise divider positioning |

| Bnding process | Disc or blister cover |

| Applicable materials | PVC,PETG,APET. |

| Cylinder length | 20-500mm |

| Cylinder dia | 40-200mm (adjustable) |