MENU

The semi-automatic PVC-PET cylinder welding machine adopts ultrasonic system welding technology. The cylinder ultrasonic welding machine has a beautiful and firm bonding effect, and the pattern and cylinder are scratch-free. The shape of the welding part can be customized, the sealing can be adjusted, and it is beautiful and high-end.

Ultrasonic automatic welding cylinder does not require glue, saves costs, and the speed is adjustable. The size of the cylinder can be adjusted at will, and the diameter and length of the cylinder after the cylinder is formed are consistent.

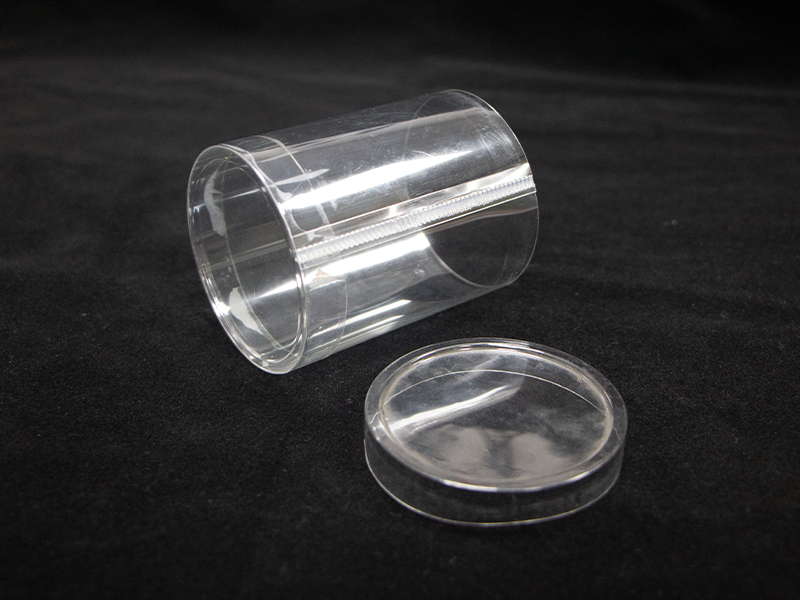

Applicable industries: Suitable for mass production of plastic transparent cylinders such as PVC, PP, APET, PETG, etc. It is an ideal packaging method for candies, gifts, toys, stationery, umbrellas, fishing gear and other products.

1: Straight ultrasonic cylinder forming method

This is the most commonly used plastic cylinder welding method on the market. It has high efficiency, clear lines, and is more beautiful. The welding process can be deep or shallow. It is an environmentally friendly and odorless cylinder packaging method.

2: Cross ultrasonic cylinder welding process

This process is mainly used for packaging with sealing requirements. If there is liquid inside, or it needs to be sealed and airtight, then choose cross ultrasonic cylinder welding. It has high airtightness, explosion-proof and drop-proof, and the welding is deeper.

3: Special welding lines for incense tubes such as candles, candle cylinder packaging, etc.

Among Buddhist supplies, candles, incense tubes, candle lamps, etc. are particularly widely used. Their packaging methods are also gradually updated with the progress of the times. At present, plastic cylinder packaging is more commonly used. This packaging method has low cost, convenient printing, adjustable size, and beautiful appearance.

| Model | HSD-190S |

| Power supply | 1P *220V |

| Pneumatic Range | 3-6KG/CM2 |

| Diameter of Cylinder | 45-200MM |

| Thickness of Material | 0.18MM-0.55MM |

| Ratde Power | 1.5KW |

| Max Length of the tube | 320MM |

| Suitable Material | PVC or PET |

| Machine Size | 700MM*650MM*1000MM(L*W*H) |