MENU

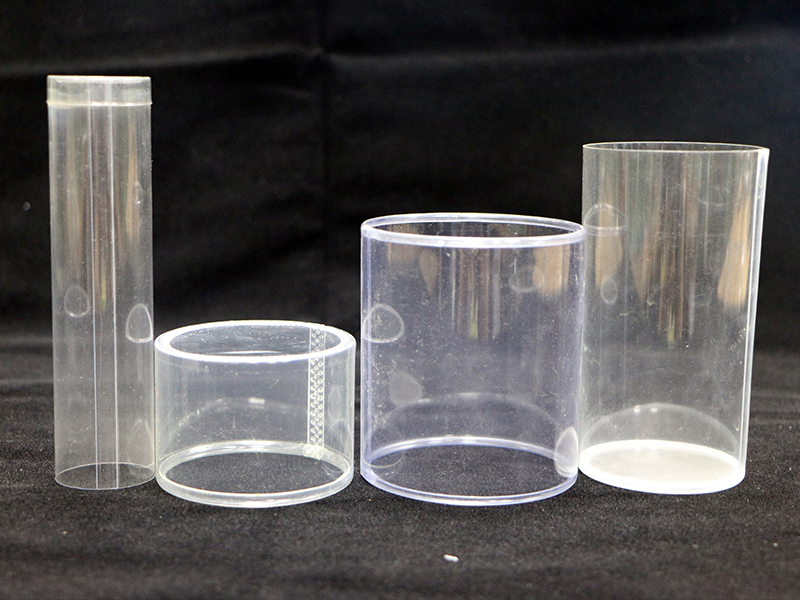

Suitable for mass production of PVC cylinder packaging, PP cylinder packaging, APET cylinder packaging, PETG cylinder packaging, plastic cylinder packaging, plastic cylinder packaging, paper cylinder packaging, paper cylinder packaging, paper cylinder packaging and other plastic transparent cylinders.

It is an ideal packaging container for candy packaging, gift packaging, toy packaging, stationery packaging, umbrella packaging, fishing gear packaging, badminton packaging, potato chips packaging, snack food packaging, cake packaging and other products....

1.Cylinder curling is fast and accurate: it can automatically complete the curling of cylinders to meet the curling requirements of cylinders of different lengths (80-350mm), diameters (30-200mm) and material thicknesses (0.3-0.5mm).

2.Applicable materials: it can be used to curl various plastic materials such as PVC, APET, PETG, as well as paper and PP materials.

3.Efficient and stable: equipped with automatic constant temperature control device and preheating function, the mold rotates at a constant speed during the curling process, which improves the curling efficiency and reduces the defective part rate.

4.Humanized design: the equipment automatically descends and automatically rises after curling. The operator only needs to load and unload materials continuously, reducing labor and improving efficiency.

| Model | HSD-2030 |

| Working Position | 2 Working Table |

| Power Supply | 220V 50Hz |

| Pneumatic Range | 3-5kg/cm2 |

| Diameter of Heating Plate | 210mm |

| Diameter of Cylinder | 40-200mm |

| Height of Cylinder | 40-300mm |

| Productivity | 11-15 Seconds/Two Tube/Two Edge |