MENU

1.Soft and hard plastic materials: Suitable for heat-sealed welding and sealing packaging of pure PVC, TPU, EVA or any soft and hard plastics, plastics, artificial leather, clothing fabrics, etc. containing 10% PVC.

2.Electronic product packaging: Can be used for blister packaging and sealing of electronic products such as MP3, MP4, MP5, toothbrushes, dental floss, toys, etc.

3.Daily necessities packaging: Suitable for packaging and sealing of various gifts, crafts, food, clothing, cosmetics, hair care products, alcoholic beverages, etc.

4.Leather products: Can be used for welding and embossing of leather, uppers, shoe materials, trademarks, belts, watch straps and other products.

5.Automotive decorations: Suitable for processing automotive interiors, automotive decorations, etc.

6.Medical devices: Can be used for packaging and sealing of medical supplies.

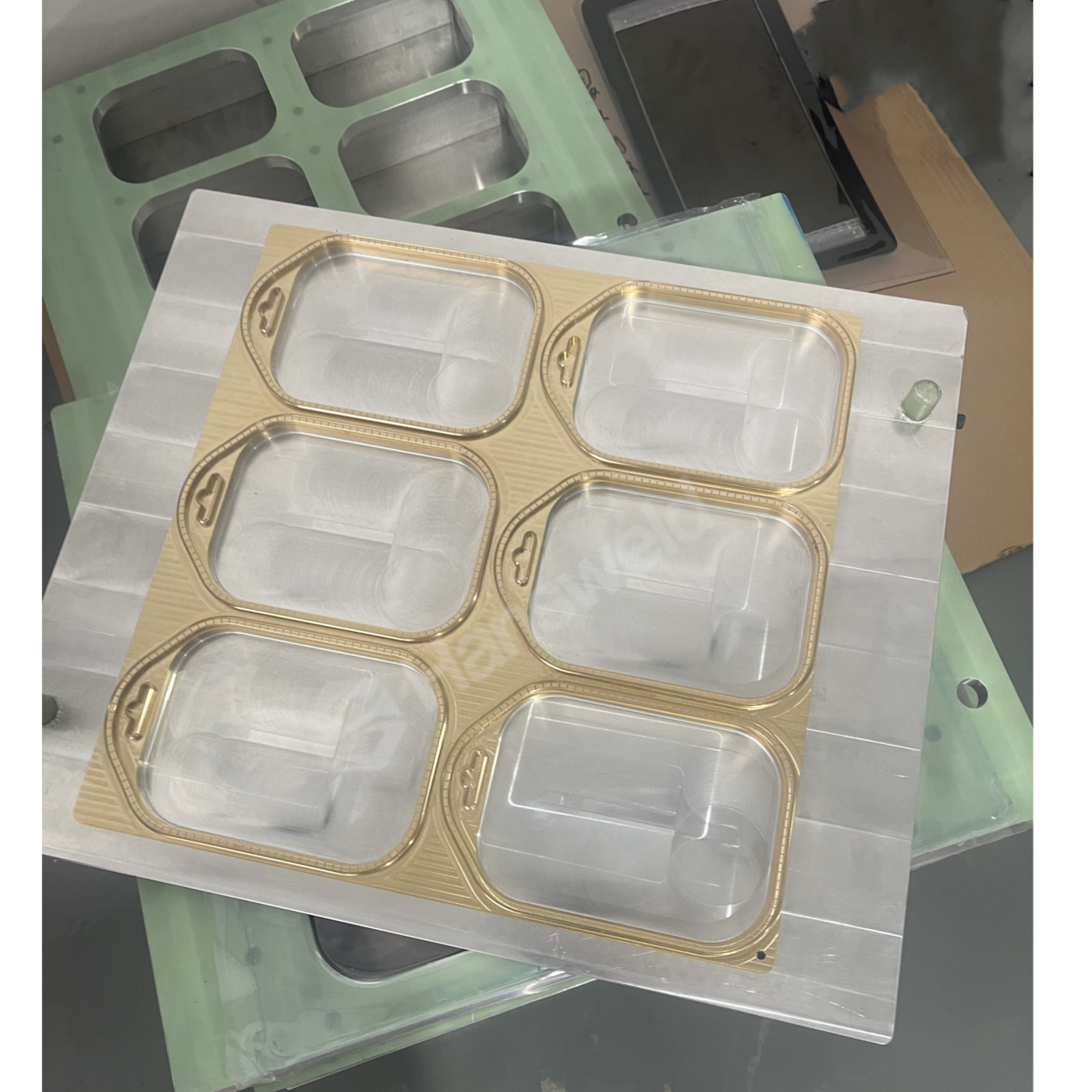

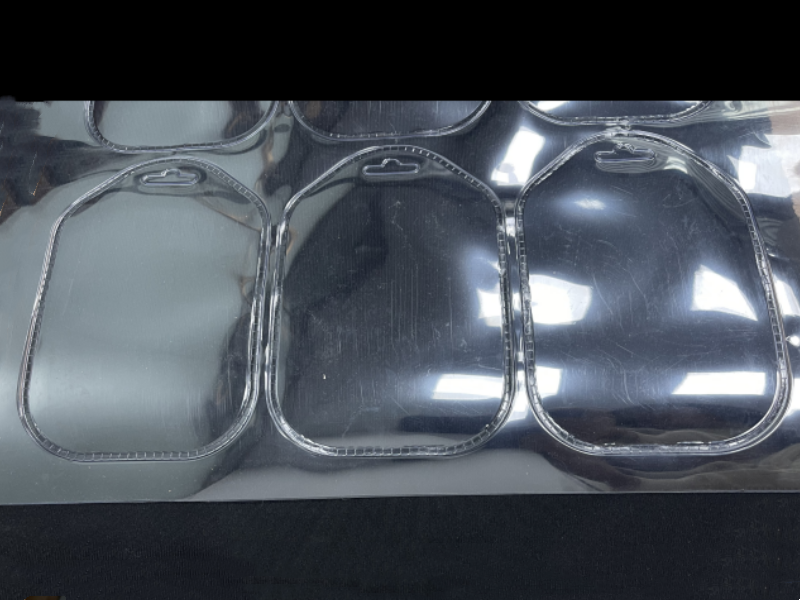

7.Other special uses: Can be used for double-sided blister blister sealing packaging, blister hanging card sealing packaging, double-sided paper clip blister cover heat sealing packaging, etc.

8.Processing of various plastic products: such as plastic welding, blister packaging, PVC plastic blister sealing, battery packaging sealing, hardware tool sealing, USB flash drive packaging sealing, etc.

1.Strong output, stable and reliable performance: It adopts vacuum tubes, with strong output power, and can stably and reliably perform high-frequency welding.

2.High-sensitivity spark overcurrent protection circuit: It is equipped with a high-sensitivity spark overcurrent protection circuit, which can effectively cut off the damage to the mold due to excessive current output, and effectively control the spark to prevent the machine from igniting and burning the mold.

3.High-frequency frequency stabilizer and shielding device: The equipment is equipped with a high-frequency frequency stabilizer and a high-frequency shielding device, which can minimize high-frequency interference and ensure the stability and safety of the welding process.

4.Multi-station fully automatic operation: The multi-station fully automatic blister packaging machine sealing machine saves manpower, has high efficiency and is easy to operate. It is suitable for bonding plastic blisters of different thicknesses. The mold can be replaced to bond blisters of different sizes and shapes.

5.Automatic control system: The machine adopts a PLC control system, and the high-precision divider rotates automatically, with a high degree of automation, easy operation and high production efficiency.

6.Efficient cooling system: It is equipped with a cooling device to control the heating and cooling time, ensure the quality of welding and improve production efficiency.

7.Safety protection device: High-sensitivity spark arrester is used to effectively prevent damage to the mold. When the current exceeds the electrical limit, the overload current relay will automatically protect the oscillator tube and rectifier.

8.Space saving and easy installation and maintenance: Shielded design is adopted, with low electromagnetic radiation, personal safety protection, small footprint, and easy installation and maintenance.

| MODEL: | HSD-ET-10KW |

| POWER: | 10KW |

| POWER SUPPLY: | 3P*380V*50Hz |

| FREQUENCY: | 27.12Mhz |

| ELETRONIC POWER: | 18KVA |

| MAX GAP BETWEEN ELECTRODE | 200MM |

| MOVING STOKE | 150MM |

| OSCILLATOR MODEL | E3069 |

| SIZE OF SEALING PLATE | 400*600MM |

| HEATING SYSTEM | 30-200℃ Adjustable |

| SEALING TIME | 0-10S Adjustable |

| RECTIFIER: | SILICON DIODE |