MENU

High frequency machines are mainly suitable for heat sealing, welding, sealing and welding of PVC and materials containing more than 10% PVC|TPU|PU|EVA|PET|PETG:

①Shoes, hats, clothing and labels: upper embossing, sole welding, insole embossing, insole welding, hat embossing, soft film embossing;

②Accessories, toys and stationery: handicraft welding, accessories welding, gift packaging, toy welding, toy packaging, toy welding, toy embossing;

③Leather and leather goods and bags: leather welding, leather embossing, leather welding, leather welding, bag embossing, towel embossing, genuine leather embossing;

④Door mats, foot mats and carpets: door mat embossing, door mat welding , plastic door mat embossing, carpet embossing, floor mat welding, foot pad embossing;

⑤ Plastic packaging sealing: plastic welding, PVC packaging bag welding sealing, plastic welding, PVC packaging bags, hot water bottles, electrical appliance blister packaging;

⑥ Medical supplies: disposable PVC packaging bags, catheter bags, catheter bags, extracorporeal drainage bags, emergency stretchers, oxygen masks;

⑦ Automotive interior products: PVC packaging bags, car door panels, steering wheel covers, anti-lattice welding, reflective sticker welding, reflective film welding;

⑧ Other welding: tent welding, canvas welding, membrane structure welding, soft film ceiling welding, PVC packaging bag skirt welding

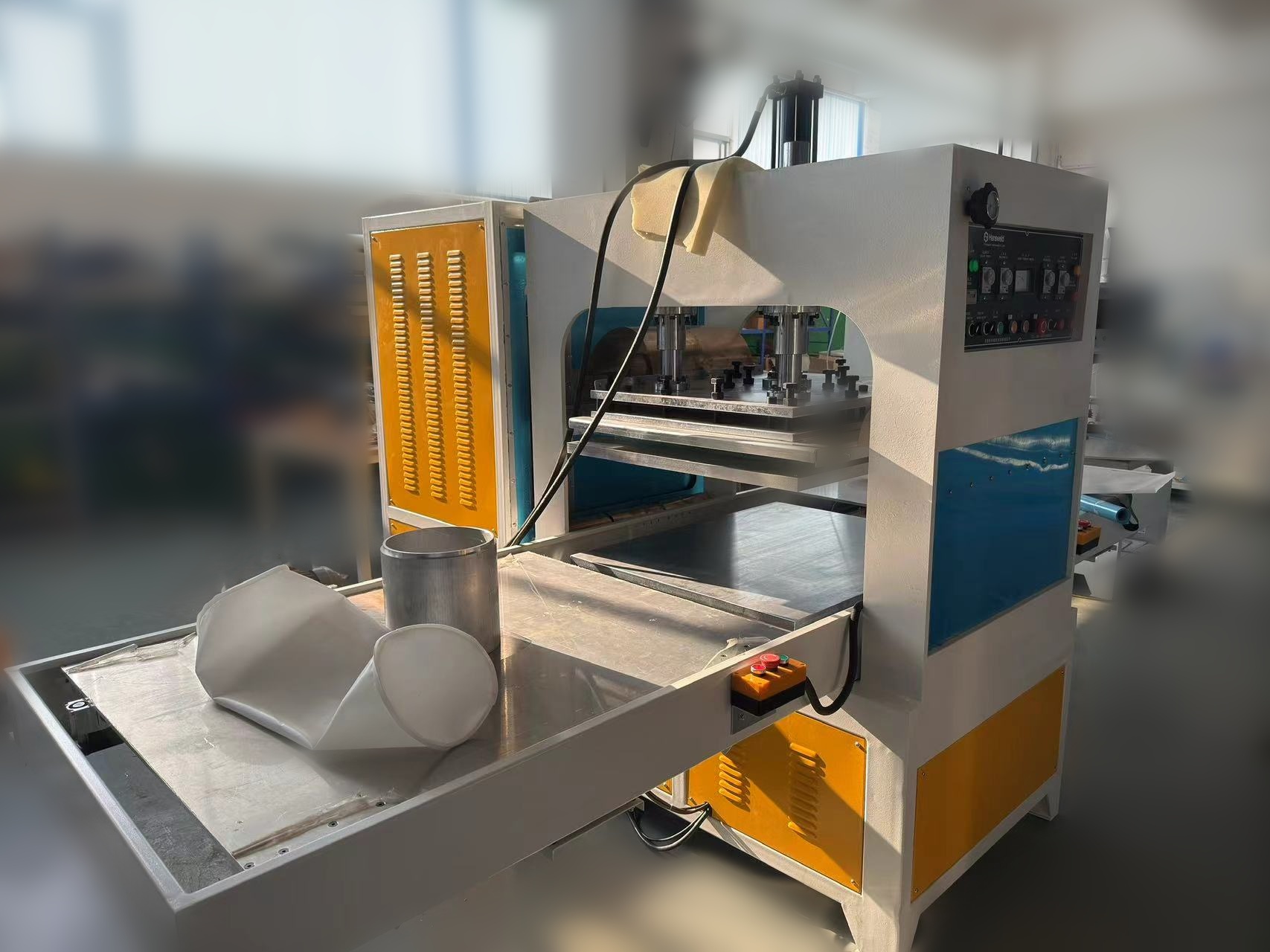

1. Mainly adopts the international industrial band 27.12MHz, which meets international standards.

2. Uses the self-developed electromagnetic wave radiation interference avoidance device system, which greatly reduces the direct radiation intensity of high-frequency electromagnetic waves to the human body.

3. According to the characteristics of plastics and plastic products that need to be heat-sealed, the temperature can be adjusted at will according to the properties of the material, mainly for heating the mold surface.

4. Adopts the latest self-flow protection device system, the main function is to protect the high-frequency electron tube from unnecessary electron tube burnout due to excessive current.

5. Adopts the anti-sparking device system, using the NL-5557 high-sensitivity spark device, which can instantly protect the high-frequency mold from burning out due to excessive current.

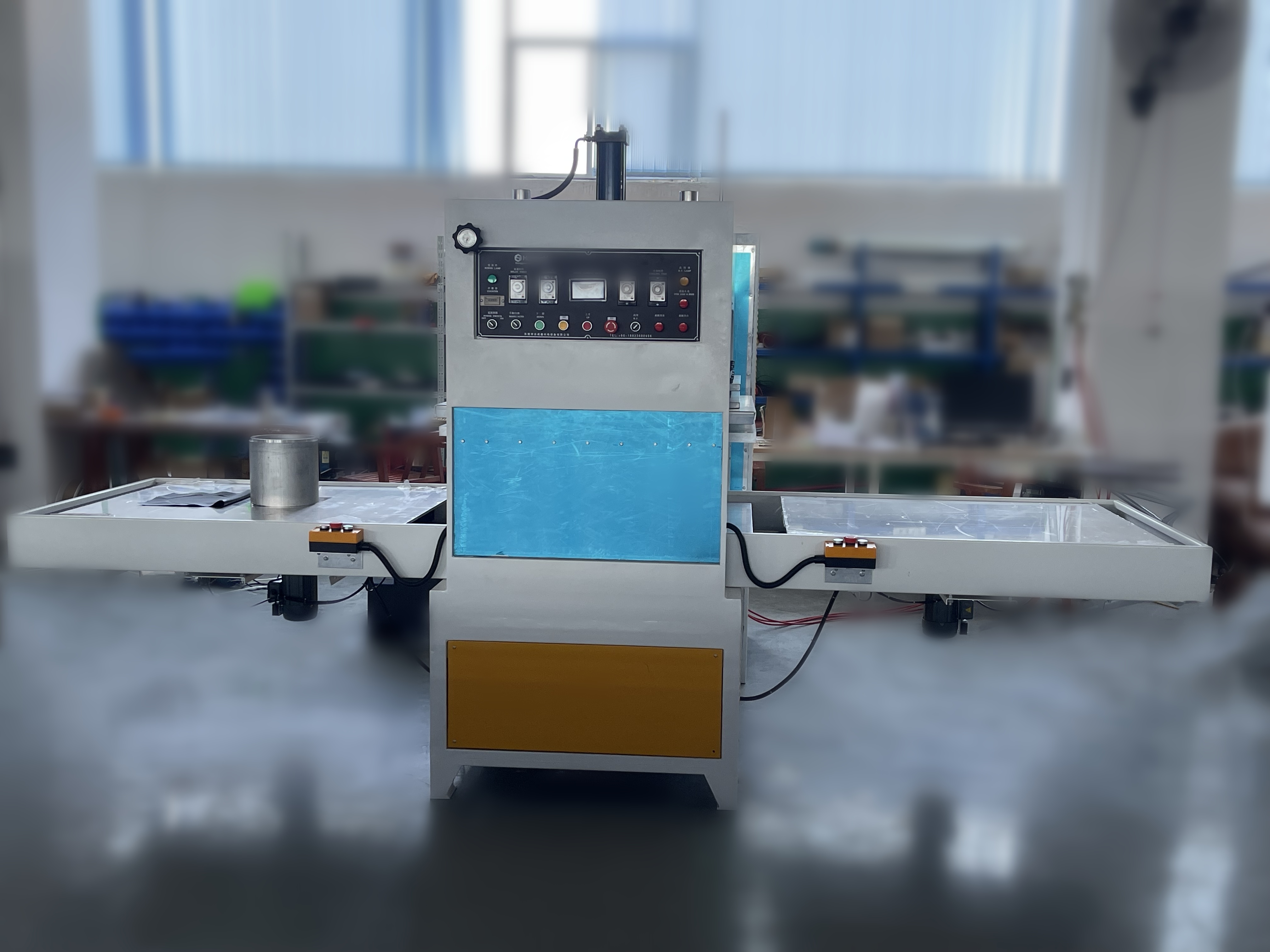

Model | HSD-25KW |

Power | 25KW |

Input power | 35KVA |

Power Supply | 380V 3P 50HZ |

Frequency | 27.12MHz |

Rectifier | Silicon Diode |

Oscillation tube | 8T85RA |

Max pressure | 2000KG |

Gap of electrodes | 250MM |

Cylinder Stroke | 150MM |

Size of upper electrode | 700*800MM |

Size of bottom electrode | 800*900MM |

Max Welding surface each work cycle | 300c㎡ |

Welding time | 0-30s |