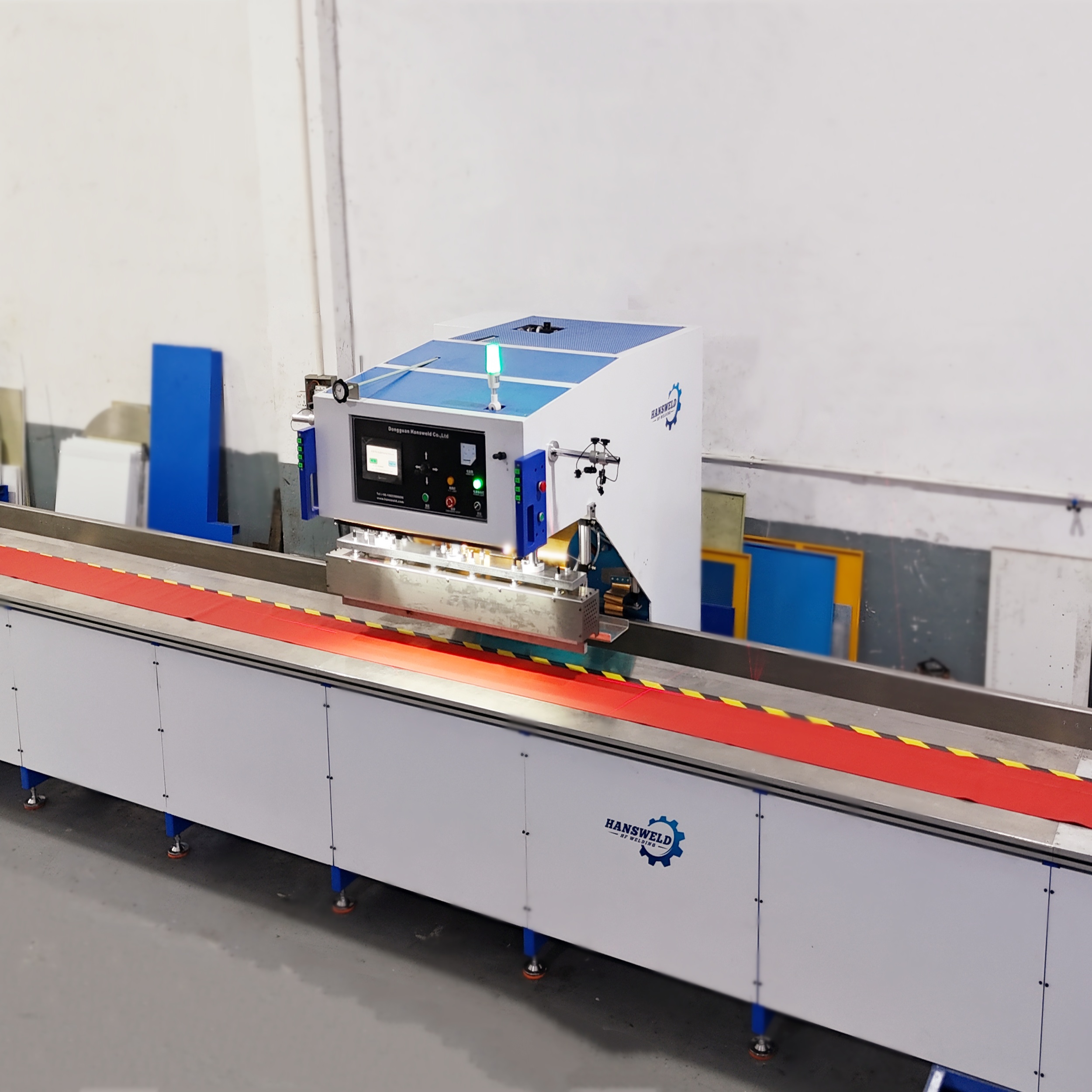

All Machines

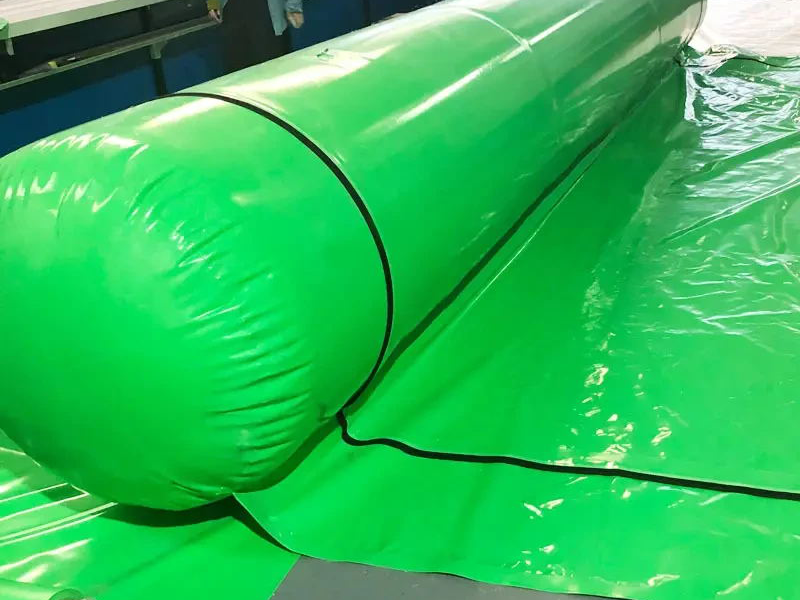

are adopted with European Design Square sytle HF generator,which is stable in power output And With High Sensitive Arc Surpressor that protect the material and welding tools Application:PVC tarpaulin ,Advertisement BannerPVC tents , tensile membrane construction , PVC ceiling,oil boom,swimming pool ,etc .

Suitable Material: PVC or TPU (Any material contents PVC or TPU.

1.It can choose machines with different high-freauency powers accordind to the needs of users, The lenath. curvoture and width of weldindmaterials can be changed each time. and the size, enoth and width of hiah-freauency molds con be chanaed to meet the needs of flmstructure welding.

2.The high-frequency oscillation system is a European-style square coaxial structure, and the high-frequency output power is stable andpowerful.

3.The high-frequency 5557 spark protection system is installed in the high-frequency welding machine to prevent damage to the high-requency welding mold.

4.The welding time can be set freely according to the thickness of the material, and the high-frequency power output can be preciselyadjusted.

5.lt welds firmly, and the thickness of the material can be satisfied. The deep and wide feeding tank of the machine is convenient for large-area continuous connection. The machine can be rotated for continuous crimping and welding, and the round-trip length can be customizedreely.

| Model | WELD-M-15KW | WELD-M-25KW |

| Suitable Welding Area | 30MM*1000MM | 50MM*1000MM |

| Voltage | AC3∮ 380V 50HZ | AC3∮ 380V 50HZ |

| Control Method | PLC/man-machine interface | PLC/man-machine interface |

| PLC | Delta | Delta |

| Servo | Delta | Delta |

| Oscillating Frequency | 27.12Mhz | 27.12Mhz |

| Maximum working pressure | 1000KG | 1500KG |

| Oscillator | 8T85RB | 8T25RA |

| Groove Size | 500*200MM | 500*200MM |

| Alignment System | Imported Rail | Imported Rail |

| Rectifier | Silicon Diode | Silicon Diode |

| Pressurization Method | Airtec | Airtec |

| Machine Color | White / or Customized | White / or Customized |

| Effective Track Length | According to customer requirements | According to customer requirements |

| Contactor and Switch | CHNT | CHNT |

| Time Relay | OMRON | OMRON |

| Pneumatic Components | Airtec | Airtec |