The ultrasonic machine can be used as a ultrasonic welding machine for other purposes in addition to the cylinder bottom cover for professional bonding of PVG, APET and PETG materials.

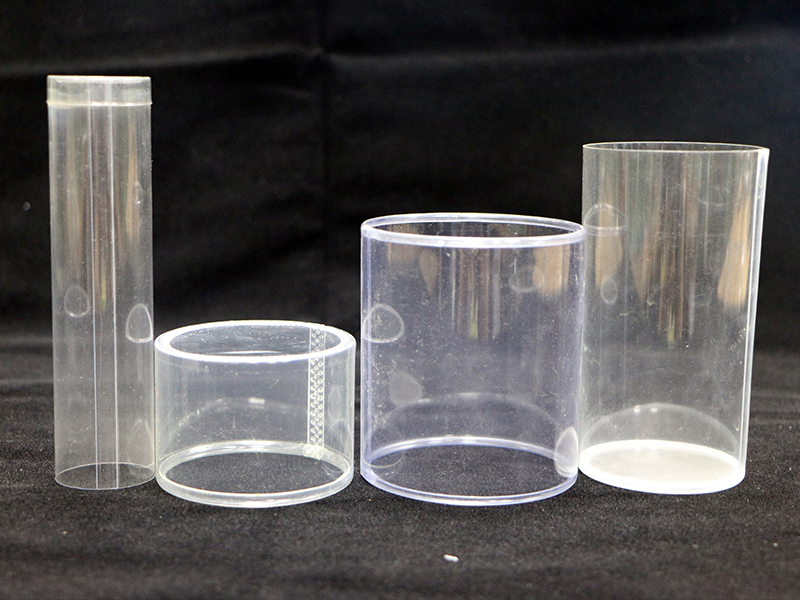

This machine can meet the requirements of bonding plastic cylinder bottom covers with different diameters (60-200mm), heights (20-400mm), material thicknesses (0.175-0.5mm), and beautiful patterns. It can also choose flat pressing without patterns;

The ultrasonic cylinder bottom sealing machine is easy to operate and efficient (adjustable in 3-6 seconds per unit), and can be used in conjunction with a fully automatic cylinder edge rolling machine to achieve assembly line production, cylinder edge rolling, and bottom sealing in one go.

1. Automatic rotary ultrasonic cylinder bottom sealing machine, suitable for transparent printing of PVC, APET, PETG, PP materials, printing cylinder bottom cover fusion, bottom cover edge sealing; Cylinder cover bottom sealing, also known as cylinder bottom pressing machine or cylinder sealing machine.

2. The relay control circuit can also be equipped with a PLC human-machine interface operating system, a four station automatic rotary table cycle drive, precise divider positioning, and ultrasonic bonding principle, resulting in a solid and beautiful effect without scratches.

3.It can meet the bonding requirements of cylinder bottom covers with different diameters, heights, and material thicknesses. The pattern is beautiful and can also be selected for flat pressing without patterns. The machine operation is simple and efficient, and it can be used in conjunction with a fully automatic cylinder curling machine to achieve assembly line production.

| Model | HSD-4200 |

| Cylinder diameter | Two horn diameter120mm、200mm |

| Working position | 4 working table |

| Power supply | 3p*380v*50hz |

| Pneumatic range | 4-6kg/cm2 |

| Cylinder diameter | 40-200mm |

| Height of cylinder | 15-420mm |

| Productivity | 2-6 s/per side |